Chemical Waste

The True Cost of Inefficient Inventory Management

This survey of 1,000 science professionals lays out the importance of chemical inventory management—and the challenges it poses.

What You’ll Learn

- Types of automated lab management tools in use, such as laboratory information management systems and electronic lab notebooks

- Satisfaction with respondents’ current chemical inventory management systems

- The benefits needed most in the lab, versus how challenging they are to attain

- The biggest pain points with managing chemical inventory

A Broken System

“We’re very serious about the chemicals we work with,” says Mark Finde is, the executive director of research biochemistry at Agenus, a Massachusetts based biopharmaceutical company. “Chemical inventory management for us is more than just following regulations—it’s about being a good citizen in our community.”

For many companies, chemical inventory management is just this: a way to ensure a safe environment for employees and the neighboring community while never being short of a needed reagent. From dedicated chemical inventory management systems to electronic laboratory notebooks (ELNs) and even humble spreadsheets, chemists today have many options for managing their inventory and staying current with changing regulations. While these systems vary in functionality, usability, features, and cost, efficient inventory management allows everyone at a company—researchers, engineers, lab and stockroom managers, technicians, and receiving clerks—not only to locate the material in the amounts they need but to respond quickly to spills and accidents.

In August 2020, C&EN surveyed readers on behalf of Merck KGaA, Darmstadt, Germany to learn how professionals manage chemical inventory and comply with regulations. Nearly 1,000 people completed the online survey, and several of them were interviewed to gain further insights. The data included here have been aggregated from survey respondents who work in the for-profit and government sectors. The respondents represented a range of occupations and industries in those sectors. Most were based in North America (84%), and just under half worked in manufacturing. One-third worked at biotechnology firms, pharmaceutical companies, or contract research organizations. Forty-two percent were directly involved in research and discovery at their institutions.

This report identifies the challenges these respondents face in managing their chemical inventories. Although it focuses on the issues raised by respondents in the for-profit and government sectors, respondents working in academic research labs raised similar issues and trends. For example, a vast majority indicated that their biggest problem was the lack of real-time information and automatic updates on the status and location of chemicals they needed. This lack led to decreased productivity and increased waste. The respondents’ con-cerns highlight the importance of CIMSs that are accurate, robust, and easy to use.

Current Practices

The respondents overwhelmingly used one or more forms of automated lab management tools at their workplaces. Such tools offer scientists functional¬ities that can include tracking chemicals as they are ordered, received, stored, consumed, and disposed of; detecting storage incompatibility; and providing safety information.

Software explicitly designed for chemical inventory management was most often cited as being used, although other laboratory automation tools, such as laboratory information management systems (LIMSs) and ELNs, were also used. Respondents working in biotechnology, pharmaceutical manufacturing, and drug development were more likely to use dedicated chemical inventory management systems than those at government organizations.

Agenus’s Findeis says that the company uses a dedicated system, which al¬lows researchers in different labs to query the database to see if a needed chemical is in another lab or on a general supply shelf.

Respondents in the for-profit and government sectors used digital information systems to manage their chemical inventory, including dedicated chemical inventory management systems, more general LIMSs, and even ELNs, which are often used to document experiment results.

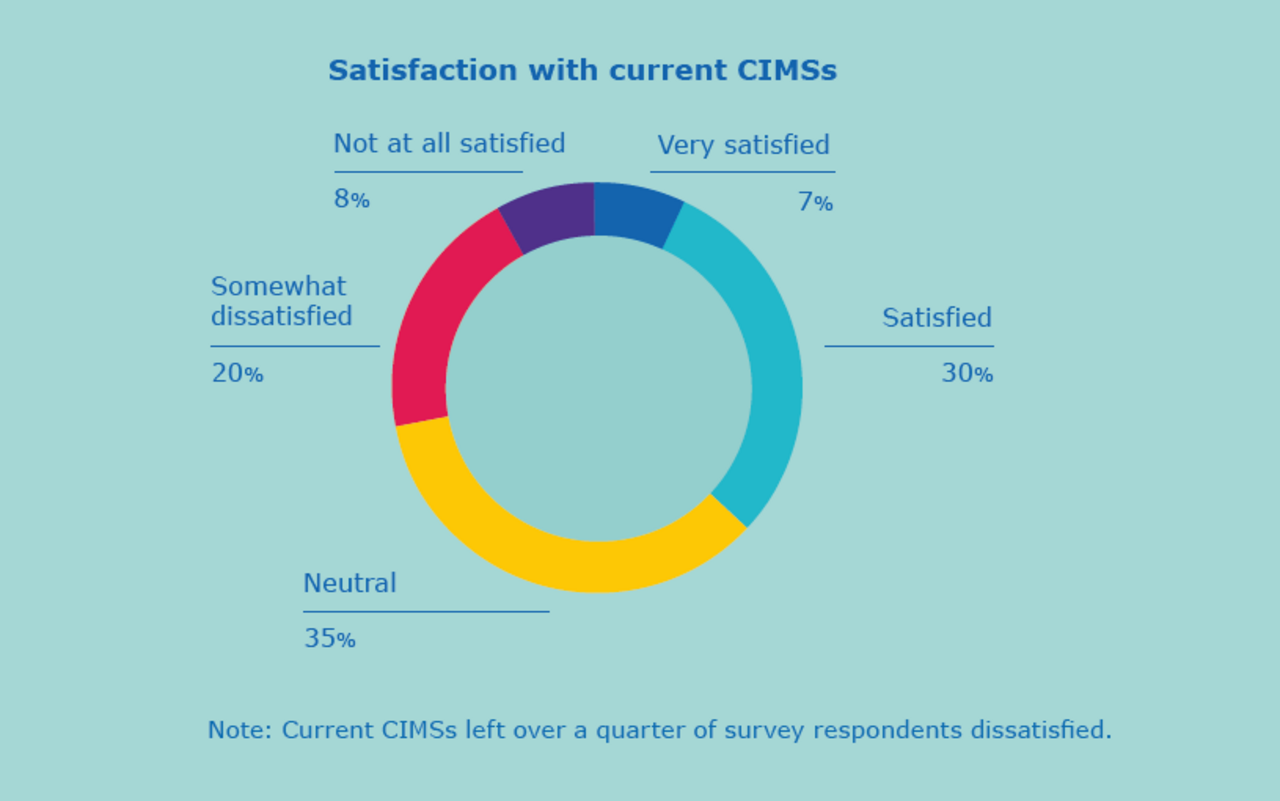

Over one-third (37%) of the respondents who used a dedicated chemical inventory management systems were satisfied or very satisfied with their system, whether it was commercial or designed in-house. A significant per-centage (28%) of those who used a dedicated system were at least somewhat unhappy, however, and noted problems with ease of use as well as a lack of real-time information and auto-updating. In fact, even those who were relatively content with their system noted that it had room for improvement.

Azlan Hussain, a principal scientist at the Malaysian oil and gas giant Petronas, has had a common experience with chemical inventory management systems and call them a “mixed bag.” He says, “They are good in the sense that the or¬ganization can keep track of inventory as well as stay in compliance with the law. However, the most productivity-killing factor is time spent searching for chemicals.”

In the COVID-19 pandemic, with nonessential employees largely having to work from home, the need for remote access to inventory management tools has moved to the forefront. Eleven percent of survey respondents said that the health crisis had influenced their views on CIMSs. Many cited the need for real-time and remote access to chemical inventory information as crucial, as fewer staff members were working in the lab at the same time—some of whom did not know where key chemicals and reagents were located.